Research and Development

R&D is the core for the development of a company. All Tullker products have independent intellectual property rights.

After several years of technical accumulation, Tullker has entered the household field since 2019, with excellent results.

Successfully developed wafer two-fluid full automatic cleaning machine for wafer, semi-conductor, lens, optical, etc.

Product Development Process

01.Market survey

02.Discuss product functions and design the rendering

03.Mechanical design

04.Structure and workmanship review

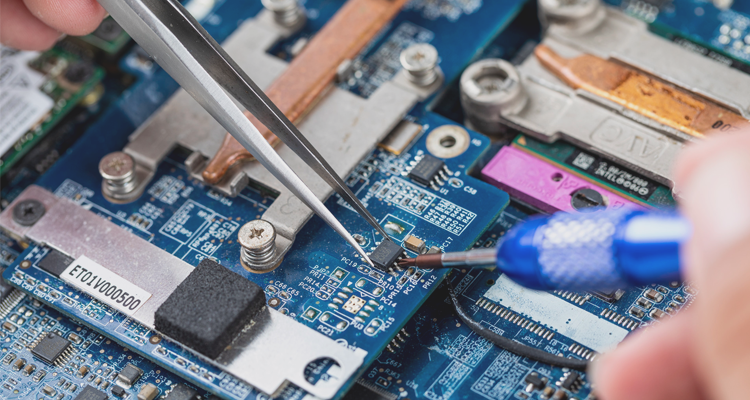

05.Schematic design

06.Matching component parameters

07.Mold audit

08.Sampling

09.Test

10.Certification

11.Put on the market

Production

3 finished product assembly lines, including 1 household series assembly line, 1 commercial assembly line, 1 industrial machine production line, with an average daily output of more than 2000 units

Tullker production line is equipped with internationally advanced laser cutting equipment and shearing bending machines

For the massive production of transducers, a professional production line from inspection, automatic welding and glue is specially designed

In order to ensure the machines are stable and reliable, all the industrial series will do aging testing for at least 24 hours before shipment.

Quality Control

In many years of cooperation with Foxconn, Beijing Beihang University and other large companies, Tuller is well-regulated with QC and pay attention to "details".

Quality control concept: "Good quality is produced, not inspected"

Implement ISO9001 quality management system

Regular training of supplier’s QC personnel, being strict in IQC and OQC to avoid defective products

Quality Control/Incoming Quality Control (IQC)

Quality Control/Inprocess Quality Control (IPQC)

QC/Finished Product Shipment QC

QC/Check QA before IQC shipment

a. Finished product inspection FQC b. Factory inspection OQC

QC/Incoming Quality Control (IQC)

Only after passing the IQC inspection can the raw materials be placed in the warehouse.

QC/Inprocess Quality Control (IPQC)

a. First article inspection; b. Tour inspection; c. Last article inspection

QC/Finished Product Production QC

All the industrial machines will perform aging testing for at least 24 hours before shipment, to ensure the performance is stable.

QC/Finished Product Shipment QC

After the aging test is finished, QC will check the accessories one by one before packing the machine in wooden frame or case.

Laboratories

Our testing center is attached to the laboratory and conducts contamination and residue analysis, compatibility testing, and quality testing of cleaning solutions

In addition, all system and innovations in Tullker originate from our testing center. For customers' specific questions about cleaning issue, new technology, ideas are turned into products in the testing center. And newly-developed products are tested here before they enter the market

Tullker has test centers in Shenzhen, Jiangsu and other places. Therefore, we are always close to our customers, providing comprehensive advice and local after-sales service

The composition and the type of contamination determine the type of cleaning media and cleaning equipment. In our testing center, we use original parts that simulate real production conditions for cleaning tests to find the ideal solution to meet your cleaning requirements

Our Services

Ultrasonic cleaning machine

Vapor degreasing, hot air, centrifugal, pulse and vacuum drying cleaning

Use spray and injection flood cleaning (IFW) in hydrocarbons, polar solvents (modified alcohol), or water-based machines

Cleanliness analysis test (VDA 19 / ISO 16232)

Product training

Maintenance training