With the development of the economy, the productivity of all walks of life is gradually increasing, and at the same time, in the production process, we will encounter various cleaning problems, and we want to remove the stains on the workpiece. Troublesome things, ordinary manual cleaning is time-consuming and laborious, the cleaning efficiency is not high and the cleaning effect is not very good.

In recent years, with the development of ultrasonic cleaning technology, the excellent cleaning effect of ultrasonic cleaning machine is deeply loved by people in various industries. Ultrasonic cleaning improves cleaning efficiency and cleaning effect, and liberates productivity to a certain extent.

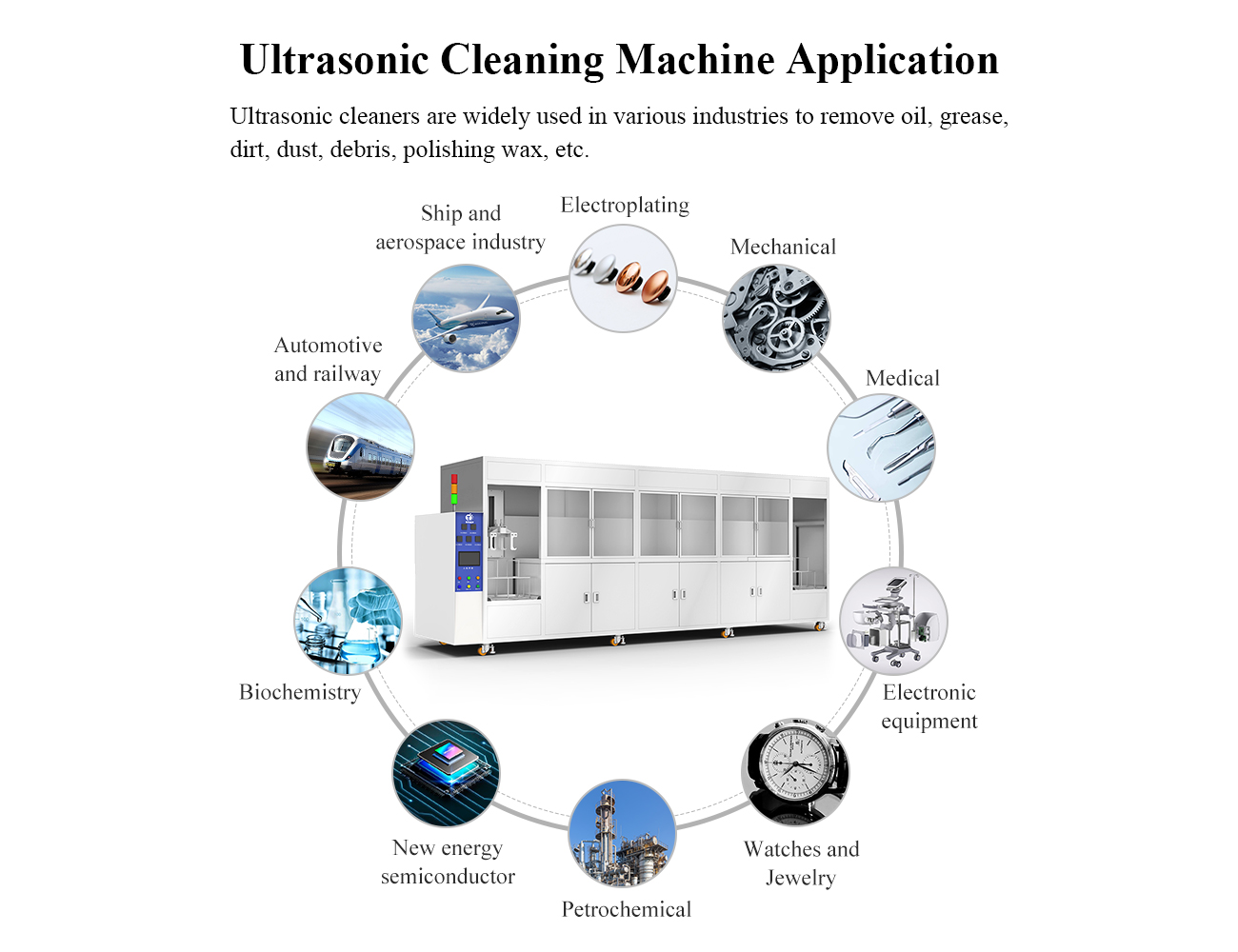

Therefore, ultrasonic cleaning is more and more widely used in various industries.

1. Surface spraying treatment industry

Mechanical chips, abrasives, dust, polishing wax, carbon deposits, scale, polishing paste, degreasing and rust removal, cleaning before ion plating, phosphating treatment, surface activation treatment of metal workpieces, polished stainless steel products, stainless steel knives, tableware, knives , Locks, lamps, hand ornaments before spraying treatment, cleaning before electroplating.

2. Machinery industry

Removal of anti-rust grease; degreasing and derusting of mechanical parts, derusting, degreasing and phosphating of engines, gearboxes, engine parts, shock absorbers, valve bodies, carburetors and various parts of automobiles and chassis before painting Pre-cleaning; dredging and cleaning of filters, piston fittings, and filter screens, etc.

3. Medical industry

Disinfection, sterilization, cleaning, etc.

4. Instrument industry

Cleaning of measuring tools, high-level cleaning of precision parts before assembly, etc.

5. Electronic industry

Remove rosin and solder joints from printed circuit boards; clean high-voltage contactors and other electromechanical parts.

6. Semiconductor Industry

Advanced Cleaning of Semiconductor Chip Wafer Body

7. Optical industry

Liquid crystal sheet, LCD substrate, glass lens, resin lens, microscope, telescope, camera lens, coated glass and other optical products, cleaning before and after coating and pre-assembly process, degreasing, sweating, dust removal, etc.

8. Watch and jewelry industry

Remove mud, dust, oxide layer, polishing paste, etc.

9. Chemical and biological industry

Cleaning and descaling of laboratory equipment

10. Petrochemical industry:

Clean metal filters, chemical containers, exchangers, etc.

The application of ultrasonic cleaning technology can simplify many traditional cleaning processes and greatly improve the quality and efficiency of workpiece cleaning. Especially for workpieces with complex shapes and high requirements, there are more advantages. Ultrasonic cleaning technology widely replaces the traditional cleaning methods of strong acid and strong alkali, which is beneficial to save resources, reduce environmental pollution, improve the working environment, reduce labor intensity, protect the ecological environment, and contribute to environmental protection.