We all know that electronic products are updated very quickly. A product can be quickly upgraded from version 1.0 to version 3.0 in just one year or even less. Although the replacement speed of ultrasonic cleaning machines cannot be compared with that of electronic products, the ultrasonic cleaning technology 10 years ago cannot be compared with today's. Now ultrasonic cleaning machines have adopted brand-new technical solutions, which are not only simple and convenient to operate, but also have cleaning capabilities and various aspects. The technical level has been greatly improved.

Before we learn about the 2.0Plus hydrocarbon cleaning machine, let’s first understand what is a “hydrocarbon cleaning agent”? Hydrocarbon cleaning agent is a new type of environmentally friendly industrial solvent cleaning agent. It is composed of two elements: carbon and hydrogen. Its main component is hydrocarbons. It is obtained by deep processing of crude oil and is formulated with active solvents, solubilizers, stabilizers, etc., so it is called a hydrocarbon cleaning agent. Hydrocarbon cleaning agent is an industrial cleaning agent widely used in Europe, America and Japan. It is used to replace trichlorethylene, methylene chloride, n-bromopropyl bromide, diesel, kerosene, gasoline, white electricity oil, Tianna water and stain removal water in large areas. Wait for non-environmentally friendly cleaning agents.

Based on the principle of similar miscibility, hydrocarbon solvents can dissolve the grease attached to the surface of hardware parts, drawn parts, precision parts, auto parts, etc., and have good cleaning power. They have been widely used in the hardware industry, electronics industry, and auto parts industry. Waiting for industrial cleaning. The hydrocarbon cleaning machine is a piece of equipment that is currently widely used and has been used in large quantities by domestic and foreign companies.

Recommend:

Intelligent PLC touch screen, sealed hydrocarbon cleaning, environmentally friendly and safe

Cleaning process:

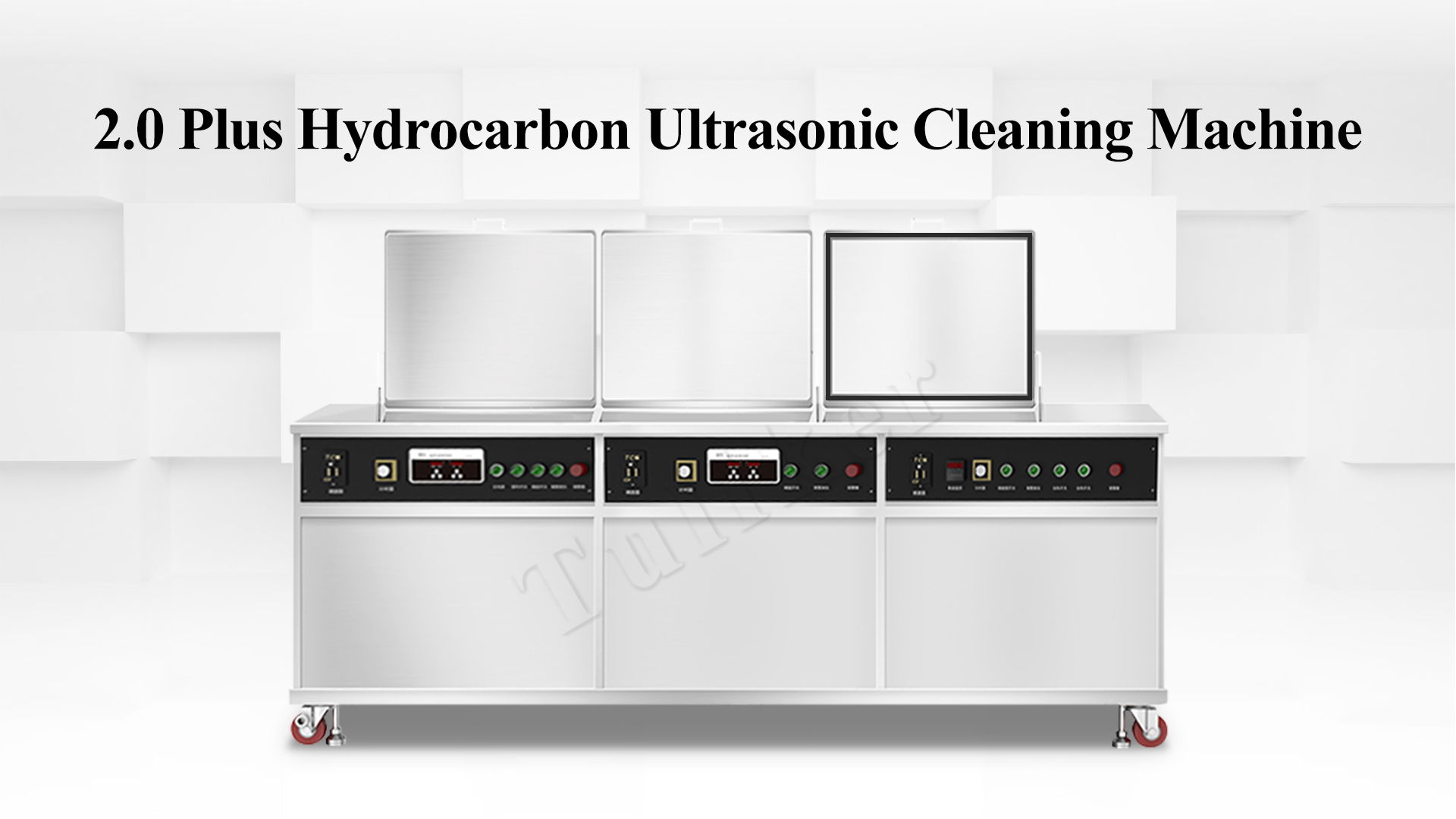

1# sealed ultrasonic rough cleaning + filtration - 2# sealed ultrasonic rinse - 3# heated hot air drying

Product advantages:

1. Equipped with PLC touch screen, the working status is clear at a glance and the operation is simple

2. It can work for a long time, and the cleaning cycle is about 3-5 minutes per basket.

3. Hydrocarbon seal cleaning to reduce solvent evaporation and improve safety

4. Equipped with a self-circulating system to effectively reduce solvent evaporation and save costs.

5. Using corrosion-resistant PP magnetic pump, the temperature is reliable

6. Heating hot air drying, shortening the drying time and making it safer

7. High-end paint technology, exquisite appearance, wear-resistant and corrosion-resistant

Scope of application:

Hardware industry, electronics industry, auto parts industry, precision parts, aerospace, battery cases, motor cases, etc.

Tullker - Makes Cleaning Easier

Tullker Co., Ltd.—an environmentally friendly industrial cleaning solution provider that focuses on ultrasonic industrial cleaning and integrates R&D, production, marketing, and after-sales. In ultrasonic cleaning, vacuum hydrocarbon cleaning, two-fluid cleaning, spray cleaning, A large number of successful cases have been accumulated in the fields of DPF regeneration and cleaning, and are sold in 96 countries around the world.