Over the years, China Aviation Development Corporation has formulated a series of cleanliness control standards for aero-engine parts, which has promoted the development of Chinese aero-engines from liquid cleanliness control to a new stage of parts cleanliness control. The compilation and release of a series of cleanliness control specifications have a great impact on cleanliness. Technical research has set out requirements and promoted the advancement of cleaning technology. Many leading cleaning technologies and innovative cleaning equipment are emerging, such as ultrasonic cleaning.

In the past, the aerospace industry generally used gasoline or alcohol as the medium to clean parts manually. The cleaning cost was relatively high, the energy consumption was high, the efficiency was low, and it caused environmental pollution. In addition, it was unable to meet the cleanliness control regulations of new materials. Nowadays, This traditional cleaning method has long been slowly abandoned. Nowadays, many manufacturers have gradually replaced traditional cleaning methods with ultrasonic cleaning technology, using safe and environmentally friendly organic solvents as cleaning media, and integrating various cleaning processes with ultrasonic cleaning equipment to meet high cleanliness cleaning requirements.

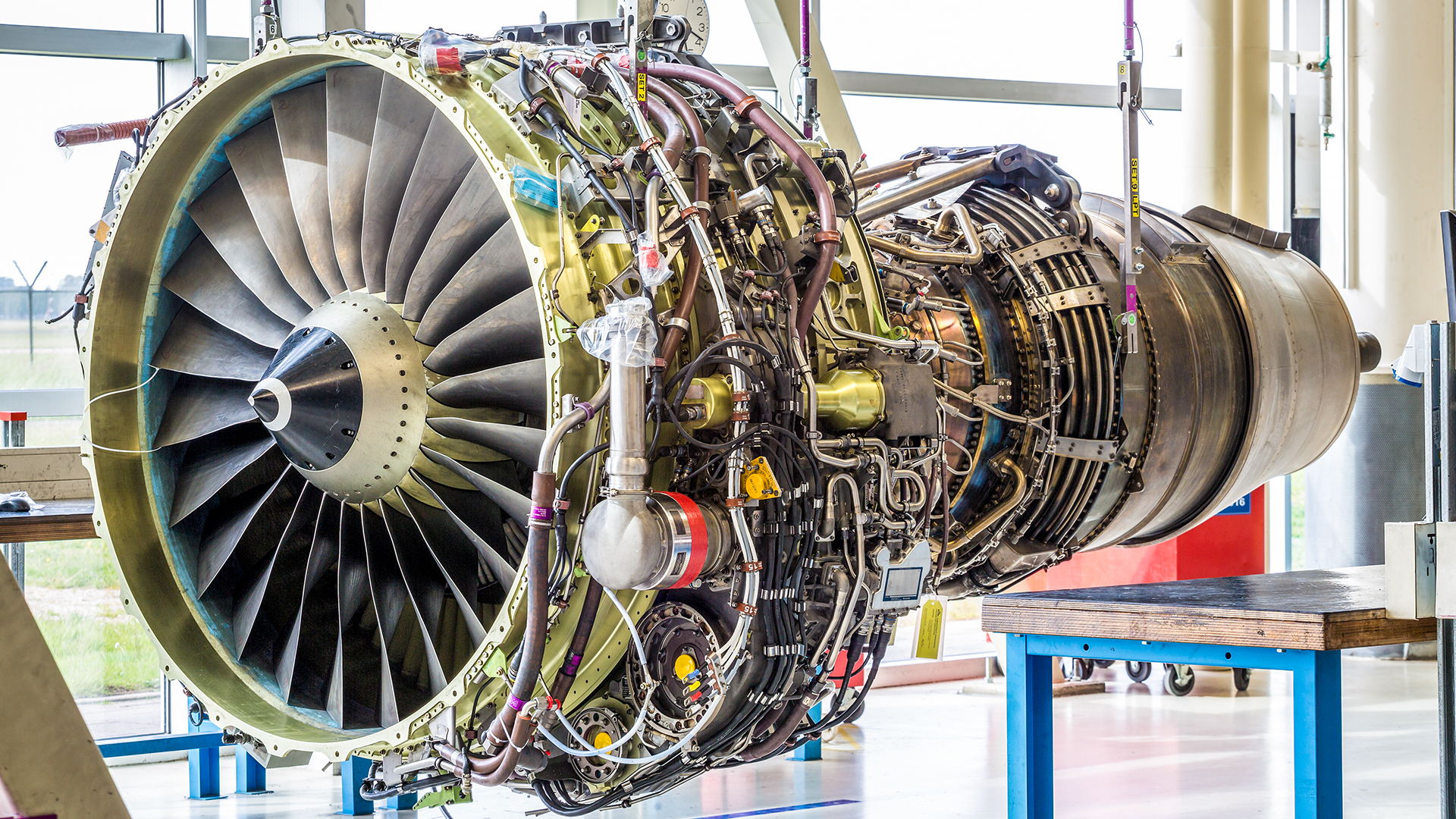

For example, aircraft engine parts cleaning Aeroengine parts are usually composed of a variety of materials, and have many complex structures on the surface, such as various pores, concave and convex surfaces, etc. Due to the working environment, various impurities will be attached to the surface of these parts, and these impurities have a great impact on the performance and life of the engine. Ultrasonic cleaning machines can effectively remove these impurities and ensure engine performance.

1.Cleaning of aerospace parts

Aerospace parts usually need to work in harsh environments such as high temperature and high pressure, so the cleanliness of their surfaces needs to be ensured during the production process. Ultrasonic cleaning machines can clean parts efficiently and finely, remove oxides and oil on the surface, and ensure their working performance.

2. Cleaning of avionics components

Avionics components usually need to work in harsh environments such as high temperature and high humidity, and these environments can cause various impurities to appear on the surface of components. Ultrasonic cleaning machines can remove oxides, stains and tiny particles from the surface so that components can work properly.

Generally speaking, ultrasonic cleaning machines are widely used in the aerospace industry and can effectively ensure the cleanliness and work efficiency of aerospace equipment. At the same time, with the continuous advancement of science and technology, ultrasonic cleaning technology is also constantly developing and improving, assisting the development of the aerospace industry.

Tullker - Makes Cleaning Easier

Tullker Co., Ltd.—an environmentally friendly industrial cleaning solution provider that focuses on ultrasonic industrial cleaning and integrates R&D, production, marketing, and after-sales. In ultrasonic cleaning, vacuum hydrocarbon cleaning, two-fluid cleaning, spray cleaning, A large number of successful cases have been accumulated in the fields of DPF regeneration and cleaning, and are sold in 96 countries around the world.