Application of Ultrasonic Cleaning Machines in Electronics Industry

Ultrasonic cleaning machines play an important role in the electronics industry and can help improve the efficiency and stability of production equipment.

Here are some applications of ultrasonic cleaning machines in the electronics industry:

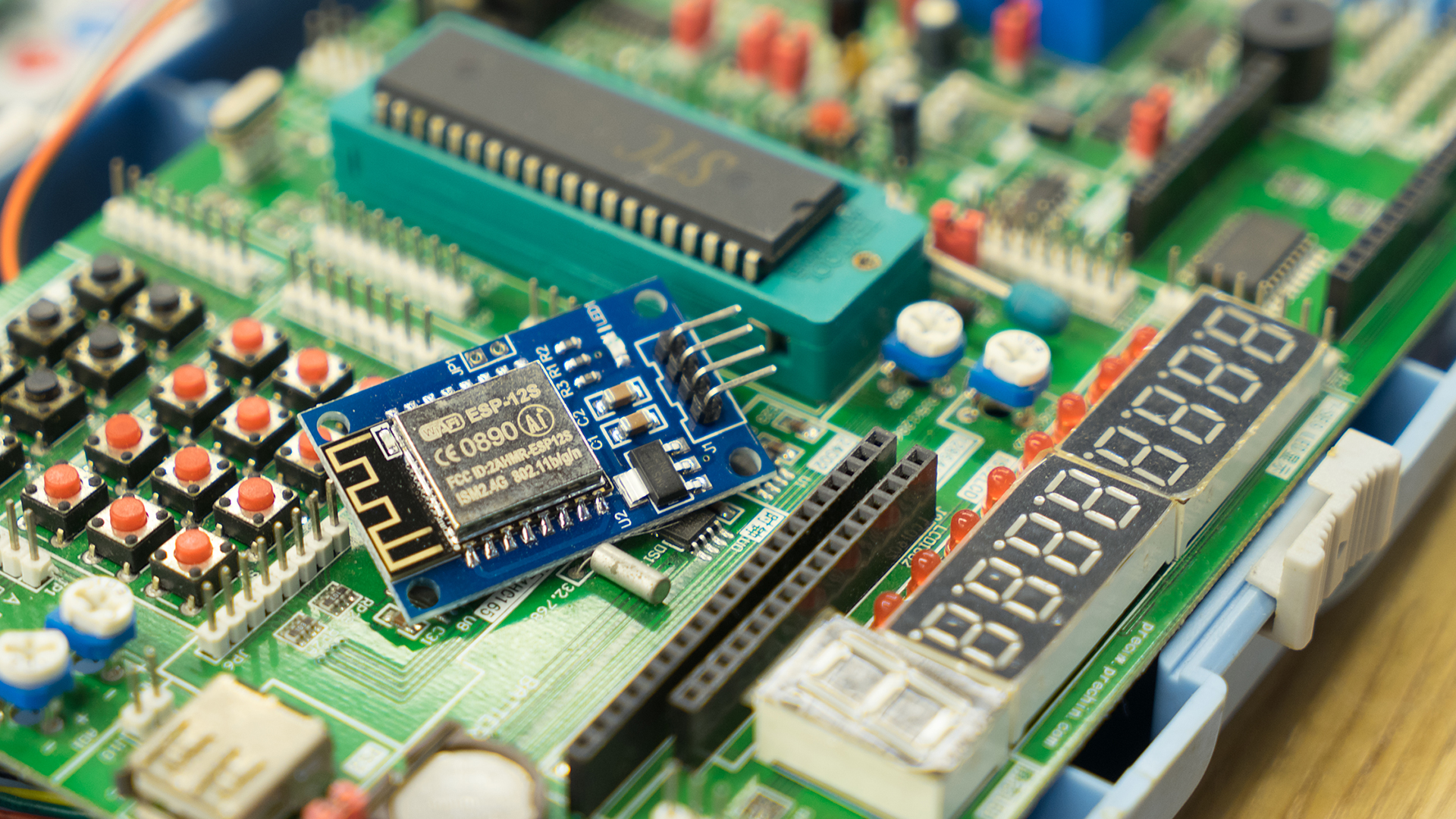

1. Cleaning electronic components and parts: Ultrasonic cleaning equipment can efficiently clean electronic components and parts, remove dirt, grease and impurities on the surface, ensuring the performance and reliability of the components. This is very important for the manufacturing and repair process of electronic products and can greatly improve production efficiency and quality.

2. Removal of welding slag: Welding is a common step in the manufacturing and assembly of electronic devices. However, the welding process produces welding slag and solder residue, which can potentially affect equipment performance. Ultrasonic cleaning equipment can effectively remove welding slag through shear force and impact force, ensuring the quality and reliability of welding joints.

3. Enhanced equipment maintenance: Ultrasonic cleaning equipment can also be used for equipment maintenance and upkeep. After long-term operation of production equipment, grease, dust and impurities may accumulate, causing equipment failure and damage. Ultrasonic cleaning equipment can clean key components of the equipment, eliminate dirt and contaminants, extend the service life and stability of the equipment, and reduce maintenance and downtime.

4. Non-contact cleaning: Ultrasonic cleaning equipment adopts a non-contact cleaning method to avoid damage to the equipment due to physical contact. Compared with traditional methods of brushing and spraying cleaning agents, ultrasonic cleaning equipment can clean equipment surfaces more gently, reducing the risk of scratches and wear.

5. Temperature control: Ultrasonic cleaning equipment is usually equipped with a temperature control system that can control the temperature of the cleaning liquid. Temperature is an important factor affecting cleaning effectiveness and equipment reliability. By controlling the temperature of the cleaning liquid, ultrasonic cleaning equipment can clean within a suitable temperature range to avoid damage to the equipment caused by too high or too low temperatures. In addition, temperature control improves cleaning efficiency and consistency, ensuring consistent and reliable results every time.

6. Cleaning agent selection: Ultrasonic cleaning equipment can select appropriate cleaning agents according to different cleaning needs. The electronics industry involves a wide variety of equipment and components, and has different requirements for cleaning agents. Ultrasonic cleaning equipment can be used with various types of cleaning agents, including water-based cleaning agents, solvents and surfactants. By choosing the right cleaning agent, you can better remove dirt and contaminants, improving cleaning results and equipment reliability.

7. Automation and programmability: Modern ultrasonic cleaning equipment usually has automated and programmable functions. Users can set cleaning parameters and processes according to different equipment and component types. This flexibility and customizability makes the cleaning process more precise and efficient.

By using ultrasonic cleaning machines, the electronics industry can more effectively clean and maintain equipment, improving production efficiency and quality. This technology has extensive application value in electronic manufacturing, maintenance, scientific research and other fields, and helps promote the development of the electronics industry.

Tullker - Makes Cleaning Easier

Tullker Co., Ltd.—an environmentally friendly industrial cleaning solution provider that focuses on ultrasonic industrial cleaning and integrates R&D, production, marketing, and after-sales. In ultrasonic cleaning, vacuum hydrocarbon cleaning, two-fluid cleaning, spray cleaning, A large number of successful cases have been accumulated in the fields of DPF regeneration and cleaning, and are sold in 96 countries around the world.