Can an ultrasonic cleaning machine clean anilox rollers?

Ultrasonic cleaning machine is a device that uses high-frequency sound waves to clean objects. This type of equipment is often used to clean small objects such as glasses, jewelry, watches, etc. However, it can also be used to clean larger objects such as anilox rollers.

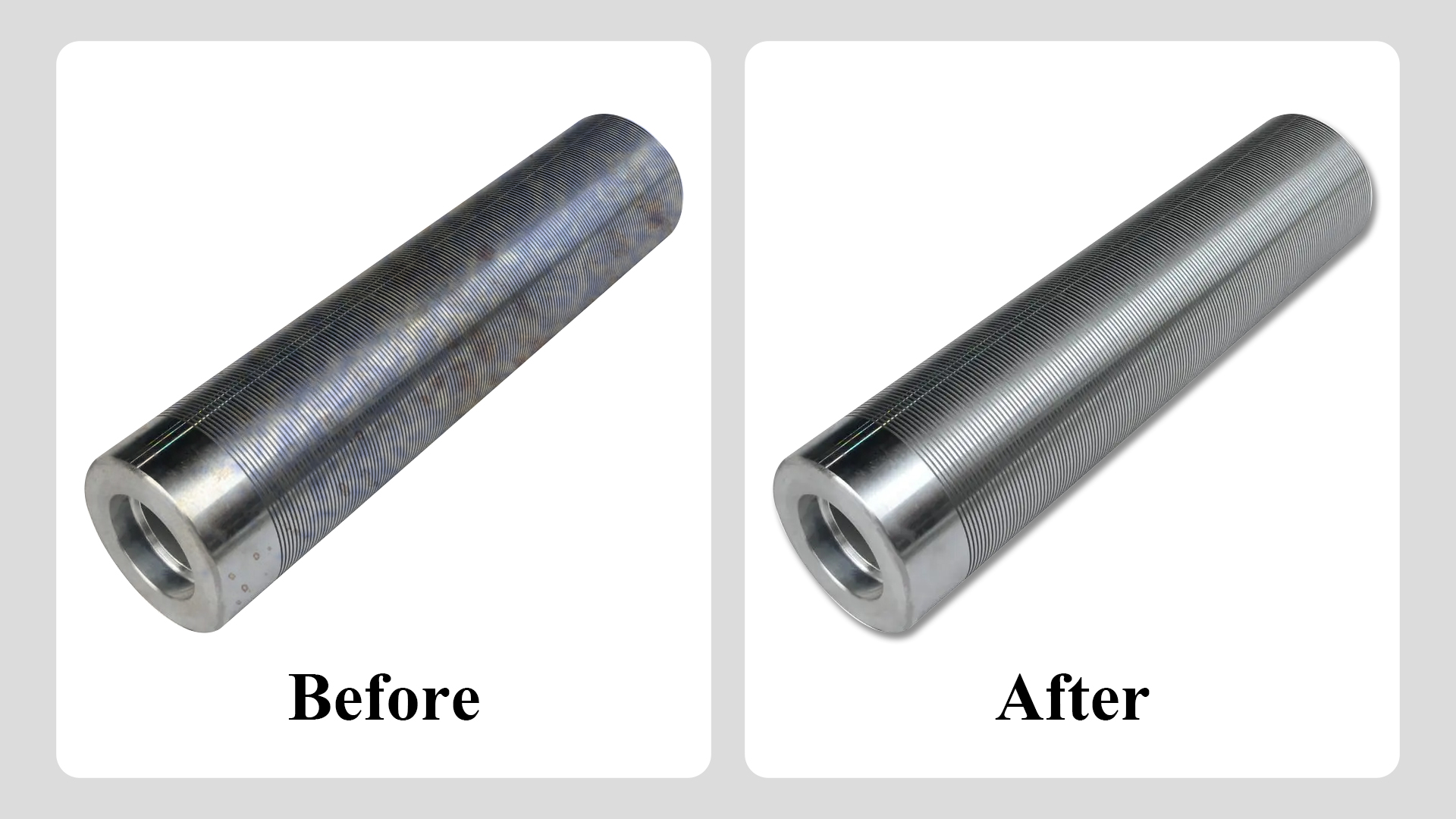

Anilox roller is a roller used in the printing industry. Its surface usually has mesh for printing. Since these meshes are easily clogged with ink, impurities, etc., they need to be cleaned regularly.

Traditional cleaning methods include manual cleaning, chemical cleaning and high-pressure water jet cleaning, but these methods have certain shortcomings, such as high labor intensity, incomplete cleaning, and damage to the mesh.

In contrast, using an ultrasonic cleaning machine to clean anilox rollers has the following advantages:

1. Thorough cleaning: Ultrasonic cleaning machines use micro-jet and cavitation effects generated by high-frequency sound waves to penetrate deep into the mesh and completely remove ink marks, impurities, etc.

2. No damage to the mesh: Since the ultrasonic cleaning machine uses a physical cleaning method, it will not cause damage to the mesh, extending the service life of the anilox roller.

3. Save time and labor: The ultrasonic cleaning machine cleans very quickly, which can greatly save cleaning time and labor.

4. No pollution to the environment: The ultrasonic cleaning machine uses environmentally friendly cleaning agents and has no pollution to the environment.

The steps to use an ultrasonic cleaning machine to clean the anilox roller are as follows:

1. Put the anilox roller into the ultrasonic cleaning machine and add an appropriate amount of cleaning agent.

2. Turn on the ultrasonic cleaning machine to generate high-frequency sound waves to clean the anilox roller.

3. After cleaning, take out the anilox roller and rinse it with clean water.

4. After the anilox roller is dry, it can be put into use.

It should be noted that when using an ultrasonic cleaning machine to clean the anilox roller, an appropriate cleaning agent should be selected to avoid corrosion or damage to the mesh. At the same time, when using an ultrasonic cleaning machine, avoid soaking the anilox roller in the cleaning agent for a long time to avoid damage to the mesh.

In short, using an ultrasonic cleaning machine to clean the anilox roller has the advantages of thorough cleaning, no damage to the mesh, saving time and effort, and no pollution to the environment. It is an advanced and efficient cleaning method.

Tullker - Makes Cleaning Easier

Tullker Co., Ltd.—an environmentally friendly industrial cleaning solution provider that focuses on ultrasonic industrial cleaning and integrates R&D, production, marketing, and after-sales. In ultrasonic cleaning, vacuum hydrocarbon cleaning, two-fluid cleaning, spray cleaning, A large number of successful cases have been accumulated in the fields of DPF regeneration and cleaning, and are sold in 96 countries around the world.