1. Introduction

With the rapid development of the electronics industry, the cleaning and restoration of micro-sized devices has become a key issue in the industry. Due to the particularity of the surface structure and size of micro-sized devices, traditional cleaning methods can no longer meet their cleaning needs. Ultrasonic cleaning machines, as a new type of cleaning equipment, have gradually been widely used in the electronics industry with their unique characteristics and advantages.

2. The principle of ultrasonic cleaning machines

Ultrasonic cleaning machines are a type of equipment that cleans the surface of an object through the vibration of ultrasonic waves. The basic principle is to use ultrasonic waves to generate tiny bubbles in a liquid, which quickly burst under the action of the sound field, thereby cleaning the surface of the object. The frequency of ultrasonic waves is generally above 20kHz, which can generate high-energy vibrations and tiny bubbles, so that they can penetrate into the surface of micro-sized devices for cleaning.

3. Application fields of ultrasonic cleaning machines

Ultrasonic cleaning machines are widely used in the electronics industry, mainly including the following aspects:

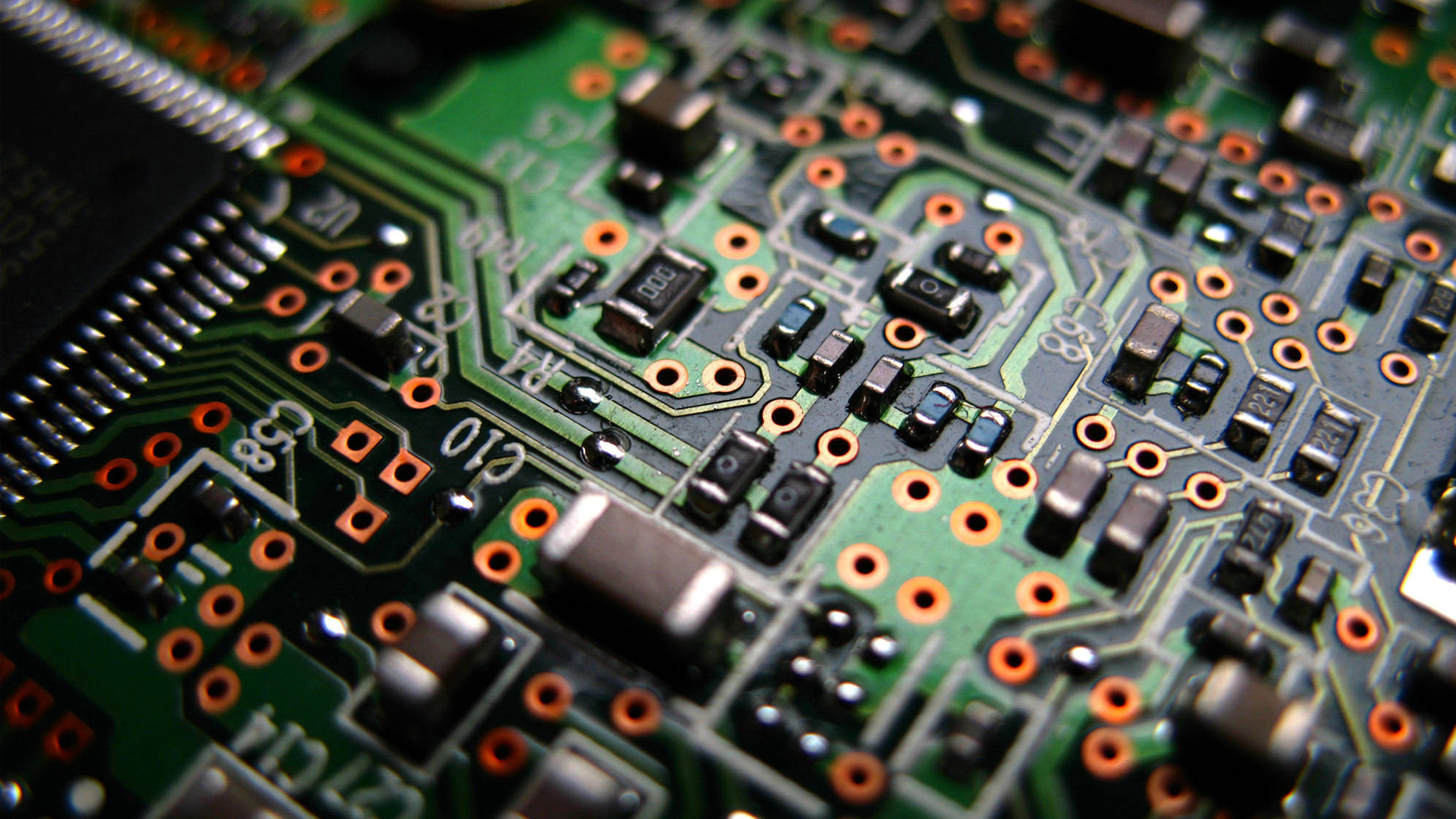

a. Microelectronics industry: The chips in the microelectronics industry are small in size and complex in surface structure, requiring high-precision cleaning and restoration. Ultrasonic cleaning machines can effectively remove dust, stains and organic matter on the surface of chips to ensure the stability and reliability of chips. 2. Optical industry: The lenses and optical components of the optical industry require ultra-high cleanliness. Ultrasonic cleaning machines can completely remove particles and organic matter on the surface, and improve the transmittance and precision of optical components.

b. Surface treatment industry: In the surface treatment industry, ultrasonic cleaning machines can effectively remove residues and organic matter on the surface of workpieces, and improve the effect and life of surface treatment.

c. Future development trend of ultrasonic cleaning machines With the rapid development of the electronics industry and the continuous updating of technology, ultrasonic cleaning machines are also constantly upgrading and improving.

In the future, ultrasonic cleaning machines will develop in the following directions:

1. Efficiency: With the rapid development of the electronics industry, the cleaning efficiency requirements of ultrasonic cleaning machines are getting higher and higher. In the future, ultrasonic cleaning machines will adopt more advanced technologies and materials to improve cleaning efficiency and shorten cleaning time.

2. Environmental protection: With the continuous strengthening of environmental awareness, the environmental protection requirements for cleaning equipment are also getting higher and higher. In the future, ultrasonic cleaning machines will adopt more environmentally friendly technologies and materials to reduce pollution and energy consumption during the cleaning process.

3. Intelligence: With the continuous development of artificial intelligence technology, ultrasonic cleaning machines in the future will adopt more intelligent technologies to achieve automated and intelligent cleaning.

The application of ultrasonic cleaning machines in the electronics industry is of great significance. It can not only improve the quality and reliability of electronic products, but also promote the rapid development of the electronics industry. In the future, ultrasonic cleaning machines will play a more important role in the electronics industry and make greater contributions to the development of the industry.

Tullker - Makes Cleaning Easier

Tullker Co., Ltd.—an environmentally friendly industrial cleaning solution provider that focuses on ultrasonic industrial cleaning and integrates R&D, production, marketing, and after-sales. In ultrasonic cleaning, vacuum hydrocarbon cleaning, two-fluid cleaning, spray cleaning, A large number of successful cases have been accumulated in the fields of DPF regeneration and cleaning, and are sold in 96 countries around the world.