The application of ultrasonic cleaning technology in the food processing industry is widely regarded as an effective method of sanitation and quality control. Ultrasonic cleaning machines can more thoroughly remove dirt and bacteria from food processing equipment, thereby ensuring the safety and quality of food.

This article will explore how ultrasonic cleaning machines can make the food processing industry more hygienic and how to improve food safety by using this technology. The food processing industry is a huge industry that involves many links from raw material collection to final product packaging. Since a large amount of water and detergent are required in the food processing process, the cleaning and sanitation of equipment has become an important issue. Traditional cleaning methods usually include manual cleaning, high-pressure cleaning and chemical cleaning, but these methods have some disadvantages, such as incomplete cleaning, waste of time and resources, and unfriendly to the environment. As a new cleaning technology, ultrasonic cleaning machines have received more and more attention and application in the food processing industry.

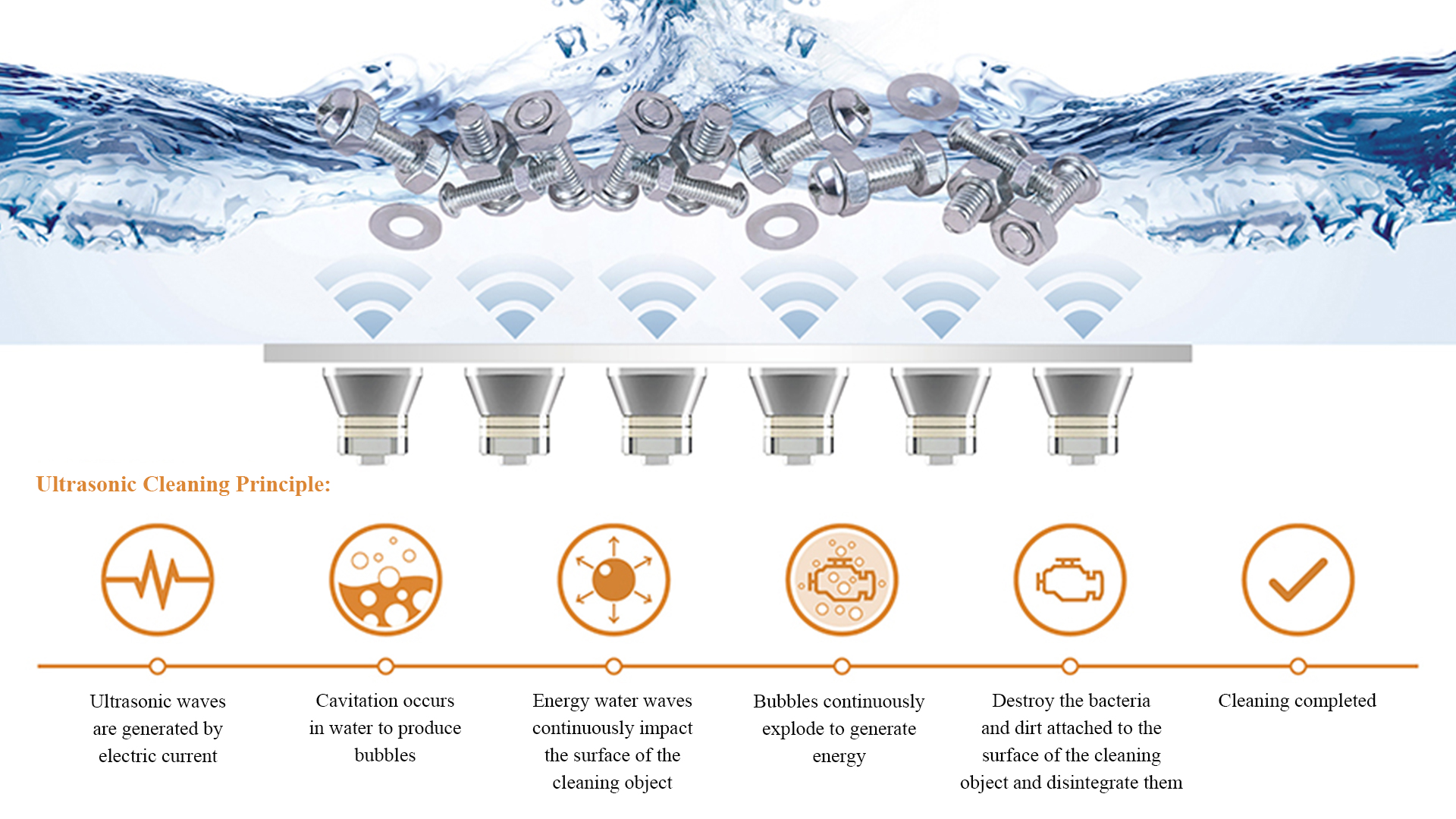

The working principle of ultrasonic cleaning machines is to use the high-frequency vibration generated by ultrasonic waves in liquids to loosen and fall off dirt and bacteria, thereby achieving the purpose of cleaning.

Compared with traditional cleaning methods, ultrasonic cleaning machines have the following advantages:

1. More thorough cleaning: Ultrasonic cleaning machines can completely remove dirt and bacteria on the surface of equipment and in small gaps in a short time, and the cleaning effect is significantly better than traditional methods.

2. Save time and resources: Ultrasonic cleaning machines can complete cleaning in a short time, and do not require a lot of manpower and water resources, which improves production efficiency.

3. Environmentally friendly: Ultrasonic cleaning machines use water as a cleaning medium, do not need to use chemical detergents, and have little impact on the environment.

4. Cost saving: Since ultrasonic cleaning machines can complete cleaning in a short time and have better cleaning effects, the use of equipment and detergents can be reduced, and production costs can be reduced.

In the food processing industry, ultrasonic cleaning machines are widely used for cleaning various equipment, such as cutting knives, containers, machine parts, etc. Studies have shown that the use of ultrasonic cleaning machines can effectively remove bacteria such as Escherichia coli and Salmonella in equipment, and improve the sanitary quality of food. In addition, ultrasonic cleaning machines can also be used for cleaning fruits and vegetables, removing dirt and bacteria on the surface, and improving food safety.