With the continuous advancement of science and technology, optical devices are increasingly used in various fields, such as photography, microscopy, optical communications, semiconductor manufacturing, etc. However, cleaning optical devices is a complex and important process because the surface of these devices is smooth and fragile, and is easily affected by tiny particles and fingerprints. In order to improve cleaning efficiency, reduce pollution to the environment and personnel, and reduce production costs, optimizing the cleaning solution for optical devices has become an urgent problem to be solved.

1. The principle of ultrasonic cleaning machine

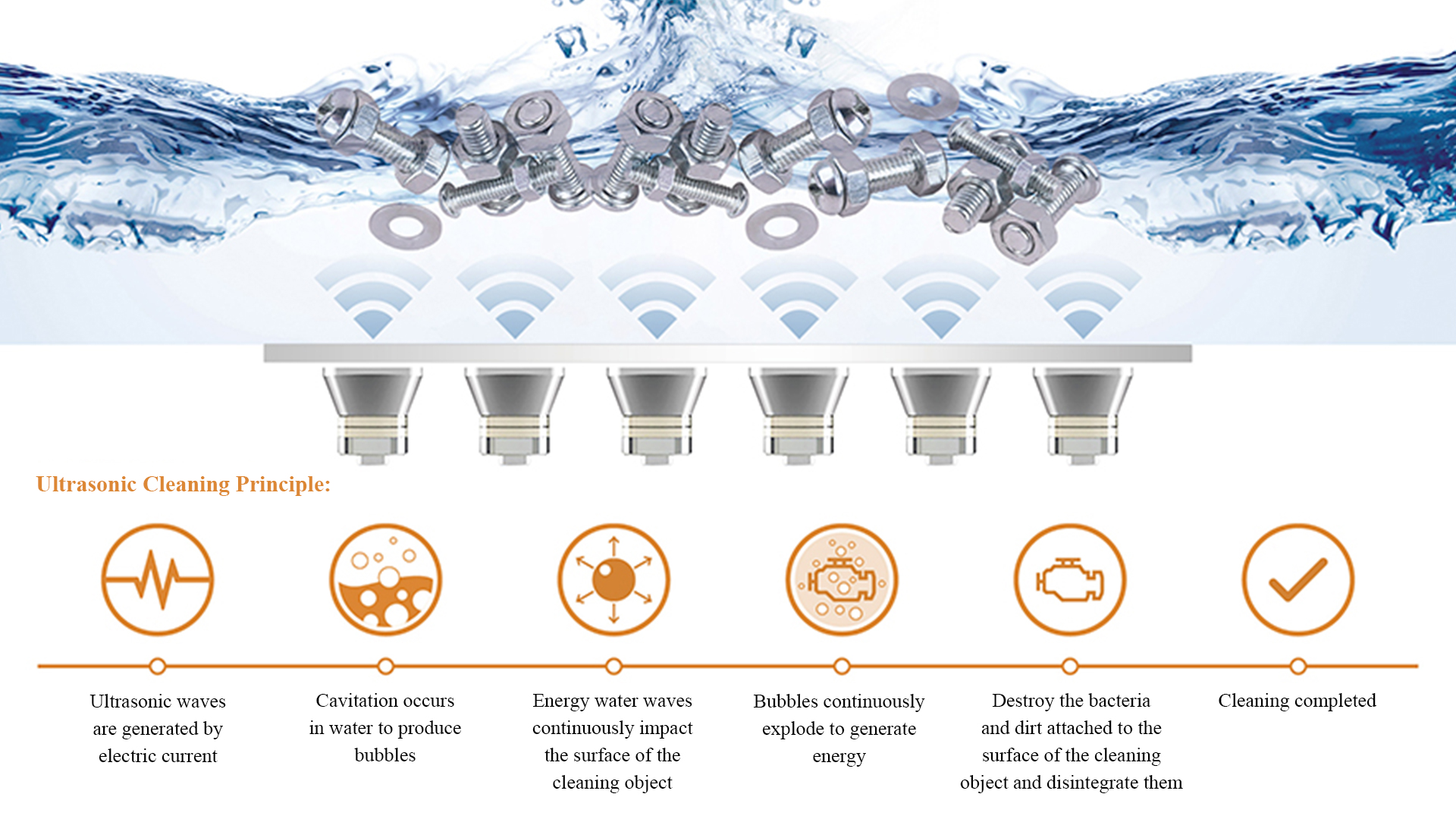

Ultrasonic cleaning machine is a device that uses ultrasonic energy to clean the surface of an object. Its basic principle is to convert electrical power into high-frequency mechanical vibration through a transducer, and then transmit this vibration to the surface of the object to be cleaned through a cleaning solvent, so that the stains and particles on the surface are separated from the object, and finally the cleaning effect is achieved.

2. Optimize the cleaning scheme for optical devices. In view of the special properties of optical devices, we can use ultrasonic cleaning machines to improve the cleaning efficiency. The following is our optimization scheme:

a. Choose the right cleaning agent. For different optical devices, different cleaning agents need to be selected. For example, for high-precision devices such as lenses and microscopes, we usually use non-fogging, non-flammable, non-corrosive, and low-toxic cleaning agents. At the same time, in order to improve the cleaning efficiency, we can add some surfactants or corrosion inhibitors.

b. Optimize the cleaning process. When using an ultrasonic cleaning machine for cleaning, we need to choose a suitable cleaning process according to the shape, size, and degree of contamination of the device. For example, for larger devices, we can use immersion cleaning, and for smaller devices, we can use flow cleaning. In addition, we can also optimize the cleaning effect by adjusting parameters such as the frequency, power, and cleaning time of the ultrasonic wave.

c. Strengthen environmental control. In the cleaning process of optical devices, environmental factors are also an important factor. In order to reduce the pollution of dust and fingerprints on the device, we need to strengthen environmental control, such as setting up a special cleaning room and installing air purification equipment. 3. Experimental research. In order to verify the effect of ultrasonic cleaning machines in optimizing the cleaning scheme for optical devices, we conducted a series of experimental studies.

First, we selected optical devices with different types and degrees of contamination, including lenses, lenses, and prisms. Then, we used immersion cleaning and flow cleaning methods, respectively, and adjusted parameters such as the frequency, power, and cleaning time of the ultrasonic wave.

Finally, we used optical measurement equipment to detect the surface quality of the device before and after cleaning, and calculated the cleaning efficiency.

The experimental results show that the use of an ultrasonic cleaner can significantly improve the cleaning efficiency of optical devices. Under the same cleaning conditions, the cleaning efficiency of an ultrasonic cleaner is about 1.5 times higher than that of manual cleaning.

At the same time, by optimizing parameters such as the frequency, power, and cleaning time of the ultrasonic wave, we can further improve the cleaning efficiency.

In addition, we found that different cleaning agents and cleaning processes need to be selected for optical devices with different types and degrees of contamination. For example, for heavily contaminated lenses, we need to use a cleaning agent containing a surfactant and increase the power and cleaning time of the ultrasonic wave. For lightly contaminated prisms, we only need to use ordinary alcohol or acetone cleaning agents, and use lower ultrasonic power and shorter cleaning time.

The ultrasonic cleaner has a significant effect in optimizing the cleaning solution for optical devices.

By selecting appropriate cleaning agents, optimizing cleaning processes, and strengthening environmental control, we can effectively improve the cleaning efficiency of optical devices, reduce production costs, and reduce pollution to the environment and personnel. This is of great significance for improving the quality of optical devices and reducing costs.

Future research can further explore the application effect of ultrasonic cleaning machines in optical devices with more types and degrees of contamination, as well as its combination with other cleaning methods (such as magnetic cleaning, laser cleaning, etc.).