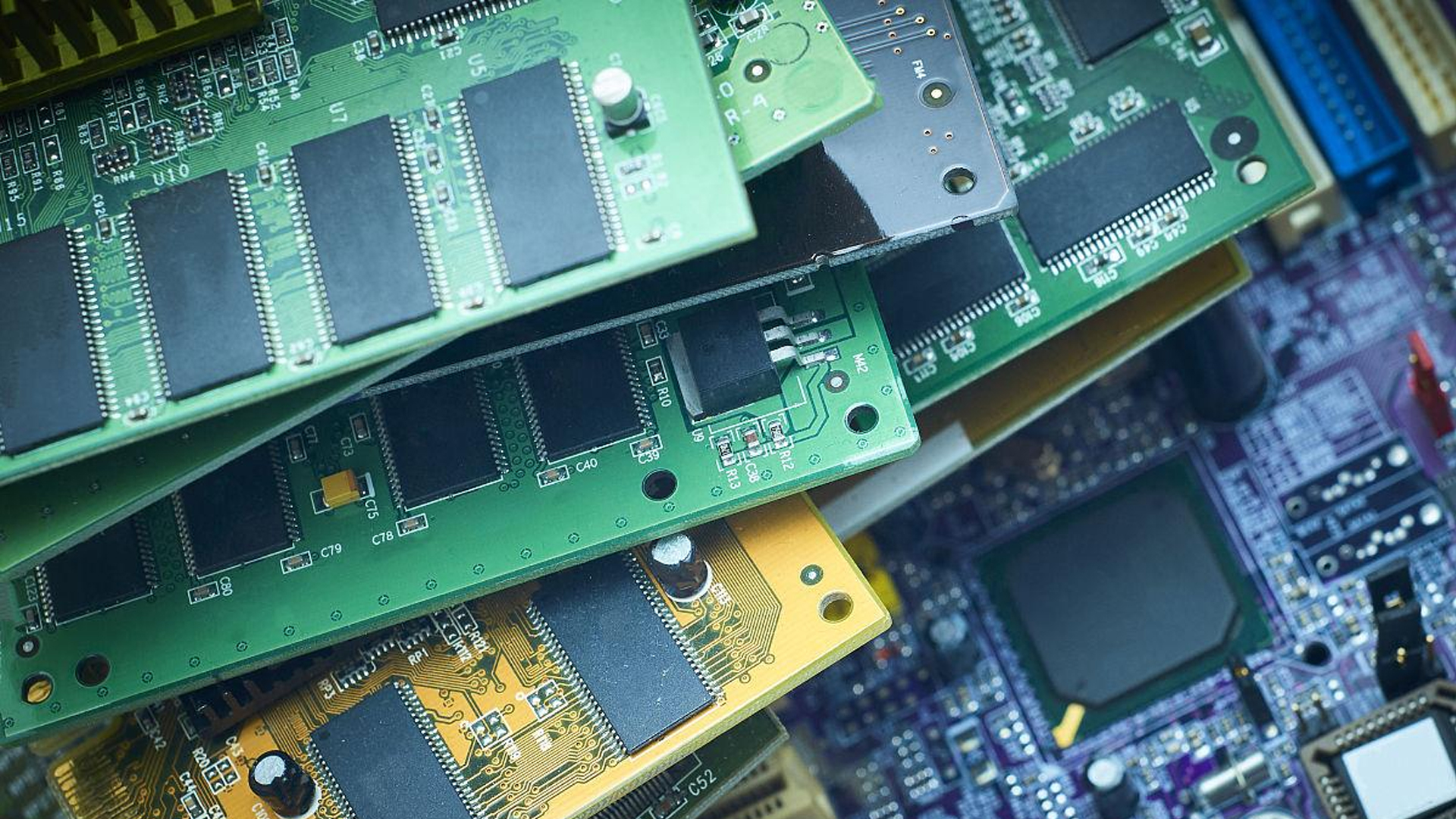

Application of Ultrasonic Cleaning Machine in Electronic Waste Treatment

The application of ultrasonic cleaning machines in electronic waste treatment is mainly reflected in the following aspects:

1. Clean the surface of electronic products: Ultrasonic cleaning equipment can effectively clean dirt and grease on the surface of electronic products, thereby reducing environmental pollution and resource waste.

2. Remove internal contamination from electronic products: Through the penetrating power of ultrasonic waves, ultrasonic cleaning equipment can remove contaminants inside electronic products.

3. Deep cleaning and recycling of parts: Ultrasonic cleaning equipment can deeply clean the parts of electronic products for recycling and reuse.

4. Reduce energy consumption and reduce environmental pollution: Compared with traditional high-temperature treatment methods, ultrasonic cleaning equipment can clean at low temperatures, thereby reducing energy consumption and avoiding environmental pollution caused by high-temperature treatment.

5. Improve the recycling rate of electronic waste: Through ultrasonic cleaning, pollutants on the surface of electronic waste can be completely removed, including grease, dust, welding residues, etc., thereby making the surface of the waste clean and helpful for subsequent recycling. The reuse or recycling process is more efficient.

6. Save water resources: During the cleaning process, a circulating water system is used, that is, water can be recycled and reused. Compared with traditional cleaning methods, the consumption of water resources can be reduced.

It should be noted that although ultrasonic cleaning has many advantages, there may also be some limitations, such as the cleaning effect of certain chemicals may not be ideal. Therefore, in practical applications, appropriate cleaning methods and equipment need to be selected according to specific needs and situations.