Ultrasonic Cleaner Provides a Solution to the Problem of Static Electricity in Electronic Components

Ultrasonic cleaning machines can solve the static problem of electronic components in the electronics industry. The following are several specific applications:

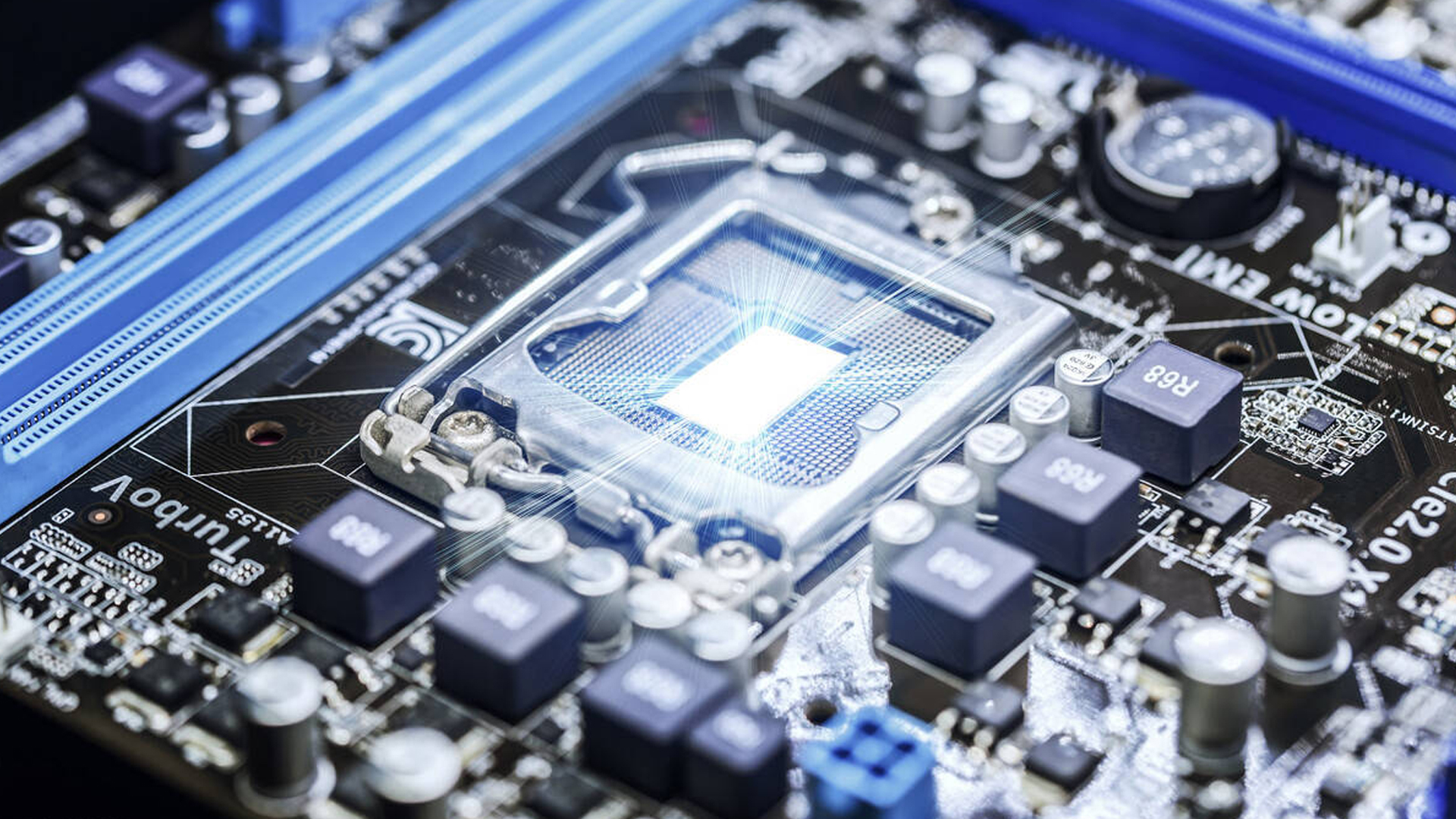

1. Clean electronic components: Ultrasonic cleaning machines can quickly and thoroughly clean the surface of electronic components to remove dust, grease and other contaminants. This is important to ensure the performance and reliability of electronic components.

2. Removal of flux residue: Soldering is a common operation in the electronics manufacturing process. Ultrasonic cleaning machines can effectively remove flux residues and ensure welding quality and reliability of electronic components.

3. Purify the printed circuit board (PCB): There may be solder, solder paste, oxide and other dirt on the printed circuit board. The ultrasonic cleaning machine can effectively remove these dirt to ensure the performance and reliability of the PCB.

4. Clean the radiator and heat sink: In electronic equipment, radiators and heat sinks are usually used for heat dissipation, but they are also prone to accumulation of dust and dirt, resulting in reduced heat dissipation effect. Ultrasonic cleaning machines can remove these dirt and improve the performance of radiators and heat sinks.

5. Avoid the effects of static electricity: Static electricity may have adverse effects on electronic components, so some precautions need to be taken to reduce the effects of static electricity during ultrasonic cleaning. Such as controlling humidity, using static eliminators, grounding and grounding, etc., and selecting appropriate ultrasonic frequency and power.

In general, the use of ultrasonic cleaning machines can effectively and non-destructively clean electronic components in the electronics industry, helping to improve product quality and production efficiency.